Virtual Technologies

Entdecken und erleben Sie

die führende DMU-Technologie

Zum Technologieführer für Digital Mock-Updie führende DMU-Technologie

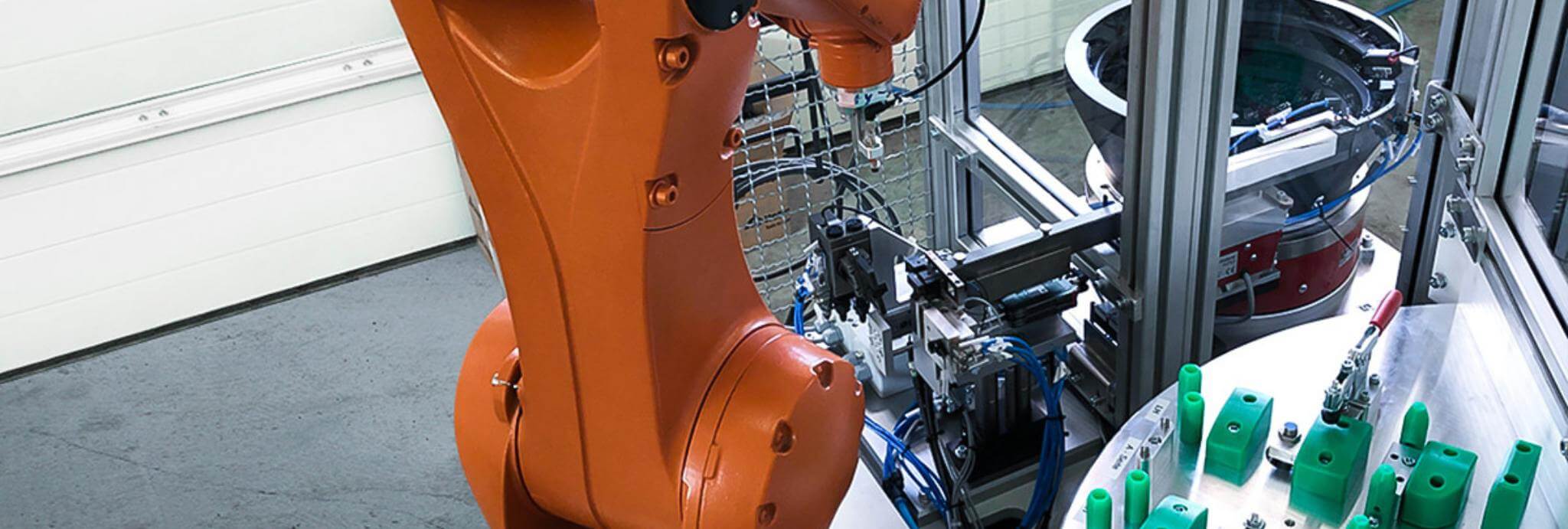

Engineering Solutions

Wir entwickeln Elektronik und (Embedded) Software:

mit invenio von der Vision bis zur Serienreife

Leistungen entdecken

Systems Engineering

Der Schlüssel zum Erfolg:

Transparenz im Projekt

Starten Sie hier Ihre Systems Engineering ReiseTransparenz im Projekt